Our machine workshop is operated from DNC/PC link or network directly from designer's computer to the workshop , where high skilled operators design their own machining programs ,giving them total control overproduction and the flexibility of roughing or finishing.

State-of the-art equipment, leading edged technological process and first-class emplyees are the guarantee to supply our customers across the world with high quality mold and products.

Sophisticated equipment has enabled us to do each and every little thing, YUANDA makes every effort to crate simple structure, more precise.stronger rigidity, longer durability and high technology product.

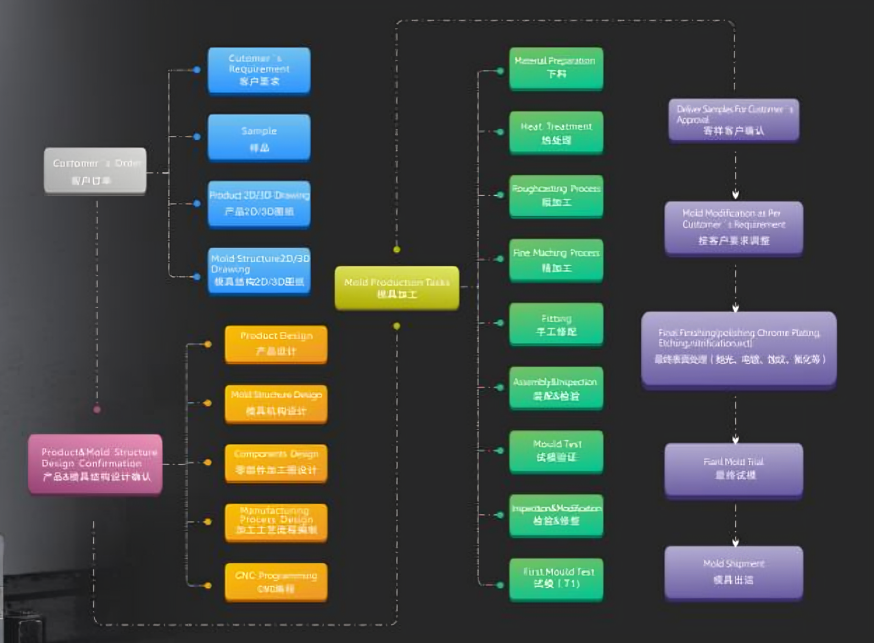

For every project, we have specific engineer invovles in every step of the mold making process and track the production schedule to ensure mold quality. Also, we will always be available to support our customers, long after the mold has been delivered and in production.