More than 300 moulds made by our compamy every year

YD mould has been in mould making and plastic injection industry for 35 years.

Provide you compective price and good quality for your plastic molding

We can provide fast and effective solution for your molding and injection.

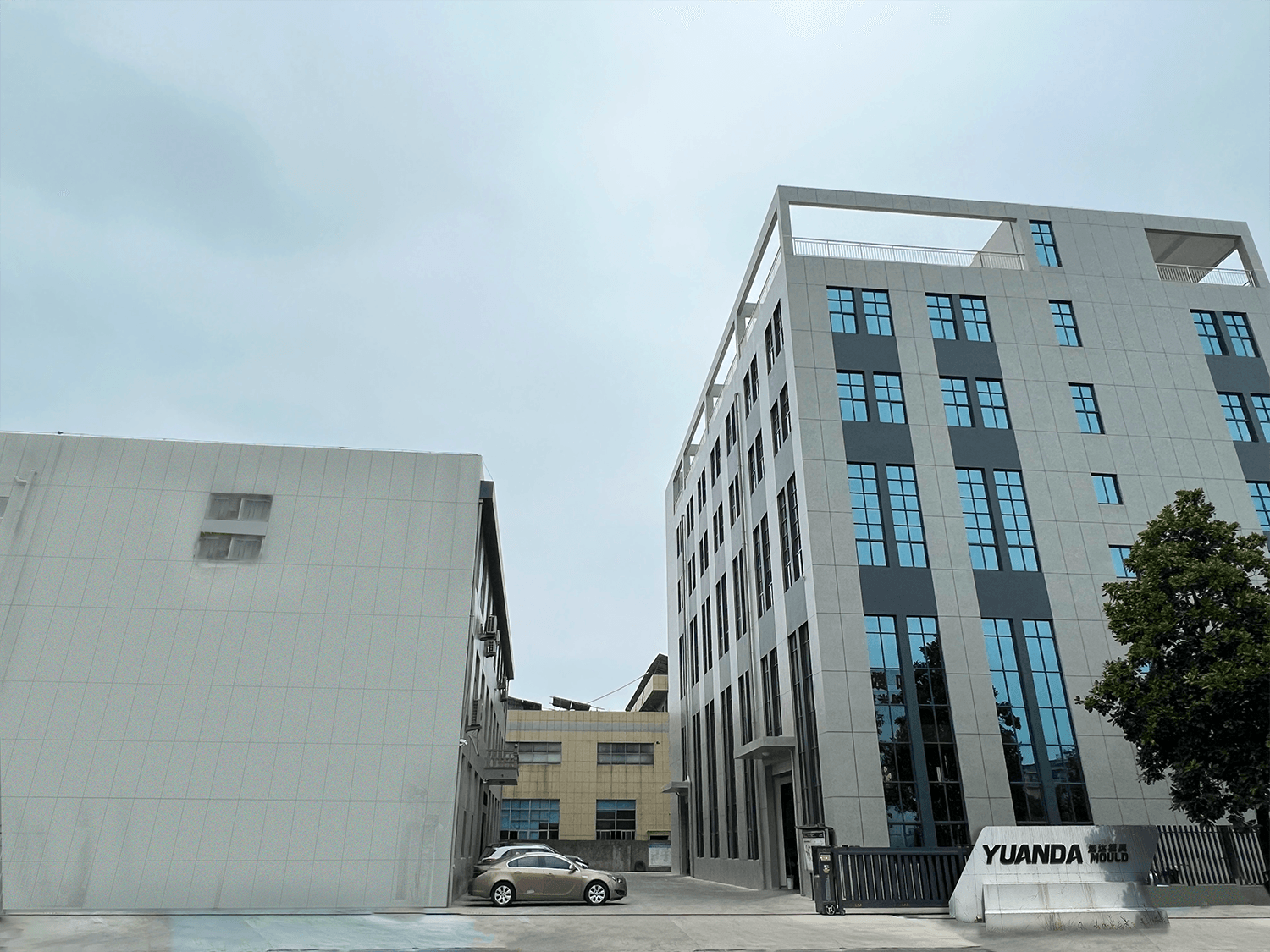

Yuanda Mould was founded at 1998 and has become one of the China’s leading mould manufacturers. Yuanda Mould innovative design, impeccable product quality, customer friendly approach and competitive pricing make it a dependable and trustworthy source of quality mould. Today Yuanda Mould products are exported throughout the world including UK, Australia, Italy, France, Argentina, Mexico, Iran, Singapore and Taiwan etc.

Yuanda Mould utilizes Pro-E, U.G. Solidworks, and Auto-CAD etc on products/moulds design, which helps establish good communications with customers as well as reduce errors to a minimum level, decrease manufacturing cost as well as lead time for development to greater extent.

Yuanda Mould unique and strict quality management system covers every ......

thin wall packaging moulds, basket moulds, box&drawer moulds, pipe moulds, garbage bin moulds, table&chair moulds, stool moulds, thin wall bucket moulds, etc.

See what is news in Yuanda Mould

We are always convinced that what shows the high end in the details is the demand for the ultimate quality service of the mould,Technology shows strength and quality wins trust.